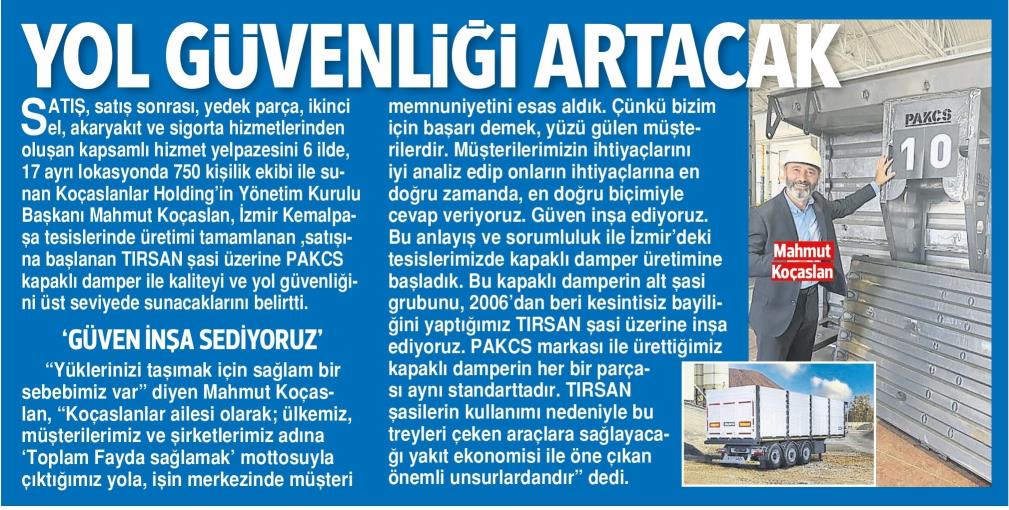

PAKCS COVER DIPPER PRODUCT PROMOTIONS HAVE STARTED

The sales team of Koçaslanlar Otomotiv, the authorized dealer of Renault Trucks for 24 years, which offers a wide range of products and services from long-distance tractors to construction and distribution trucks in Turkey, attended the product training held at the PAKCS production facility in Izmir Kemalpaşa on Saturday, February 12. successfully completed. In the training attended by Koçaslanlar Automotive's General Manager Mesut Süzer, Sales Directors Ahmet Sezer and Ahmet Güler, Business Development Manager Cüneyt Görkem, Sales Support Specialist İlknur Arslan, Business Development Officer Gonca Başaraner and sales consultants, all production stages of PAKCS Cover Damper, used The focus was on the quality and technical specifications of the components.

Erol Turan, PAKCS Production Manager, emphasizing that high quality and robust materials are used in all production stages of the PAKCS Lid Damper, said, “As PAKCS, we have focused on the robustness and reliability issues of our lid damper both in the design and production stages. For this reason, we have paid special attention to using the highest quality and robust materials at every point of our product. The sheets we use are SSAB's products, and SSAB produces by using only iron ore without using scrap materials in its production. This increases the quality, strength and flexibility of the material to the highest level. In the welding technology we use, it is ensured that the product quality is at the highest level by using the methods prescribed and recommended by SSAB. In addition, production is carried out in fixtures at all stages and minimization of sheet stress is ensured. This also provides ease of supplying spare parts to the user Jul. The parts that become finished products are first washed with phosphating and chemicals in the washing cabinet and cleaned from the oils on them. Then, it is sandblasted in the sandblasting cabinet and made ready for painting by separating foreign substances. the paint quality is brought to the highest level by being painted untouched in the paint booth with a 16 meter long oven. The paint we have used is PPB branded paint, which is accepted from automotive manufacturers all over the world. The damper coming out of the paint is matched with the TRUCK chassis at the installation site and its installation is completed. The hydraulic system we have used is HIDROMAS and the hydraulic system is taken as a set and installed. It is important to take it as a set in terms of giving a full guarantee of HYDROMAS. Thanks to all these and our quality-oriented production approach, PAKCS Lid Damper meets the needs of our customers in the best way." said.

Emphasizing that the training is very useful for all personnel, PAKCS Sales Director Mehmet Demir said, “The durability of the product, the ease of access to the spare parts, the long service life will provide our customers with great advantages in operating costs. As PAKCS, we have also done a serious study on the robustness, which we consider to be the most important element. PAKCS quality, combined with TIRSAN chassis, has brought a new breath and new quality standards to the sector. The aim of our training is to be able to offer your customers every stage of production, the quality of the materials used and the workmanship. In this context, we had a very informative and enjoyable day.” he spoke.